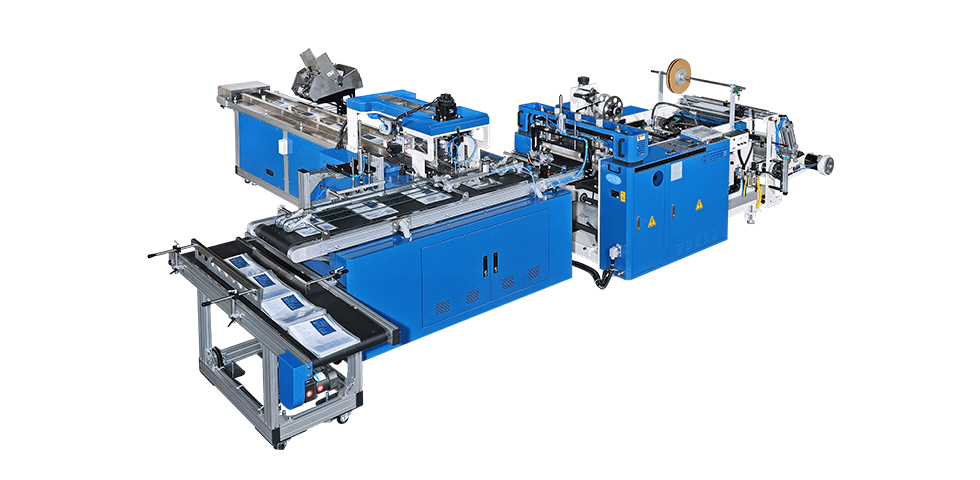

Fully Automatic Paper Inserting and Packing Machine

Applications

Auto Packed Flyer Bag

DESCRIPTION

Fully Automatic Paper Inserting and Packing Machine

CWSS+IP is a fully automatic servo driven OPP and PE side sealing bag making machine with paper inserting and packing device.

Machine Features:

-

Machine body is made of thick steel frame for stability at high speed operation.

-

One set Japan made YASKAWA servo motor and servo drive control bag's length precisely and stable speed, reducing electric consumption.

-

Bag's length and production speed can be set easily on the touch screen.

-

Automatic lift up film roll unwinder with air shaft, reducing the number of employees.

-

Automatic tension control of plastic film roll on main machine.

-

E.P.C (Edge Position Control) to keep the film at correct position.

-

Self-adhesive tape inserting device and adhesive tape cover removing device.

-

Hole punching device (Ø6 mm).

-

Two sets German made photocell SICK for printed bags and lack of plastic bags on the conveyor belt.

-

Paper feeding path (3 meters) connecting to paper inserting device, insert paper into side sealed bag piece by piece.

-

Three sets Japan made YASKAWA servo motor and servo drive control paper insert, paper feeding and packaging.

-

Air suction vacuum pump keeps bags in the stable position on the conveyor belt.

-

Automatic side sealed bag’s flap closing device to finalize an A4 size flyer.

-

Machine stops automatically when:

- Bags jammed.

- Film is finished or broken.

- Temperature below the setting.

- Print is not at correct position.

- Paper feeding jammed.

Add to Inquiry

TECHNICAL DATA

| MODEL | CWSS+IP-500 |

|---|---|

| Bag Width (mm) | 150 ~ 300 |

| Bag Length (mm) | 200 ~ 345 |

| Thickness/Layer (mm) | 0.03 ~ 0.05 |

| Production Speed (cycles/min) | 30 ~ 50 |

| Max. Film Roll Size (Ø × W) | Ø 450 × 345mm |

| Paper inserting thickness (mm) | Max. 10 |

| Power Required (kW) | 5.5 |

|

Air Volume Air Pressure |

700 L/min 6 kg/cm² |

|

Dimensions L X W X H (cm) |

645 X 555 X 150 |

|

Packing L × W × H (cm) |

230 X 320 X 170 230 X 400 X 170 |

| Net Weight (kg) | 1800 |

| Gross Weight (kg) | 2200 |

With over 40 years of experience

Our goal is to manufacture high quality machines and provide fast after sales-service to customers.